7075

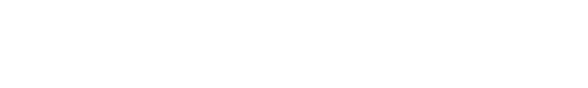

7075 aluminum sheet belongs to Al-Zn-Mg-Cu superduralumin, which is a cold-treated forging alloy with high strength and hardness, far better than soft steel. Due to the fine grain structure inside 7075 aluminum alloy, it has excellent deep drilling performance, enhanced wear resistance of tools, good mechanical properties and anode reaction.

Category:

Download:

Share:

Product introduction

7075 aluminum sheet belongs to Al-Zn-Mg-Cu superduralumin, which is a cold-treated forging alloy with high strength and hardness, far better than soft steel. Due to the fine grain structure inside 7075 aluminum alloy, it has excellent deep drilling performance, enhanced wear resistance of tools, good mechanical properties and anode reaction. At present, 7075 aluminum sheet is the preferred metal material under the requirement of lightweight conditions with lower density and higher hardness. It is one of the most potential alloys for commercial use.

|

Alloy |

7075 |

|

Temper |

F、O、T6、T651、T7451、H112 |

|

Thickness(mm) |

1-500 |

|

Width(mm) |

<2600 |

|

Use |

Gao Erfu ball joint, mold, parts, etc |

Performance: (1)Compared with 7075 aluminum sheet, 7050 aluminum has higher corrosion resistance and better toughness. (2)Has lower quenching sensitivity. This allows it to maintain its strength properties, stress corrosion cracking resistance and fracture toughness levels. (3) The cold workability of 7050 aluminum sheet is not good, but it can be processed. (4)7050 aluminum sheet also has good anodizing reaction. (5)Welding methods are not recommended, such as brazing, gas shielded arc welding or coated metal arc welding.