Product introduction

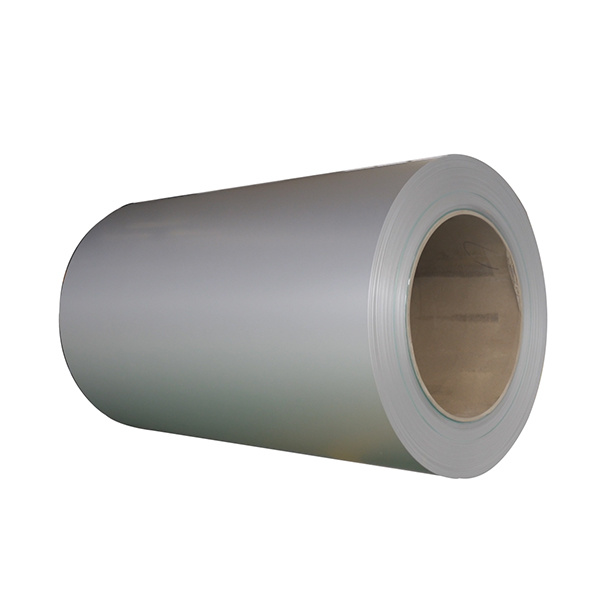

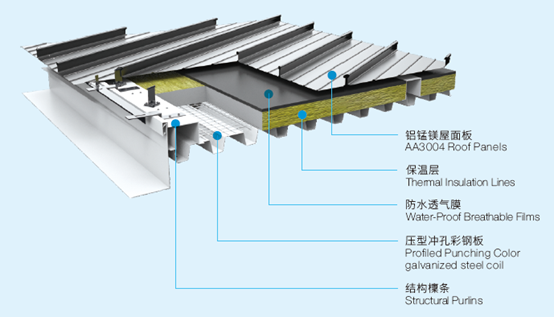

3004 prepainting aluminum coil are made from 3004 mill finish after degreasing, cleansing and passivated layer processing, and currently most advanced and durable coating materials manufactured by KANAR500 and HYLAR5000 seriess of polyvinylidene fluoride (PVDF) resin. The products are finally molded through other secondary operations including cutting, pressing, punching and bending, which can be applied in overall roofs and building coil for wall decoration with a long span and a large area, be used for decorative coil of interior roofs through being cut into small coil, bending and stamping die processing, and be used for energy-saving exterior wall decoration coil bonding with foaming polyurethane or honeycomb aluminum

Size

|

Substrate size: |

Thickness 0.2-1.5mm Width 600-1850mm |

|

Film thickness: |

single-coated 4-20 micron double coated 25-28 micron 3 coated 35-38 micron |

|

color |

According to our company to provide a model, but also can be customized according to customer needs any color |

Product Advantage

01

Being exposed to natural light and detected in Florida, USA, weather-proof quality assurance for over 20 years

02

The products boast characteristics of high strength and corrosion resistance, due to advantages of raw materials

03

Realize multiple colors or single colour, according to clients’ demands for different colors

04

Easy formability by processing, changeable manufacturing spans and areas for cutting, pressing, punching and bending